MIM Procedure

1. Definition

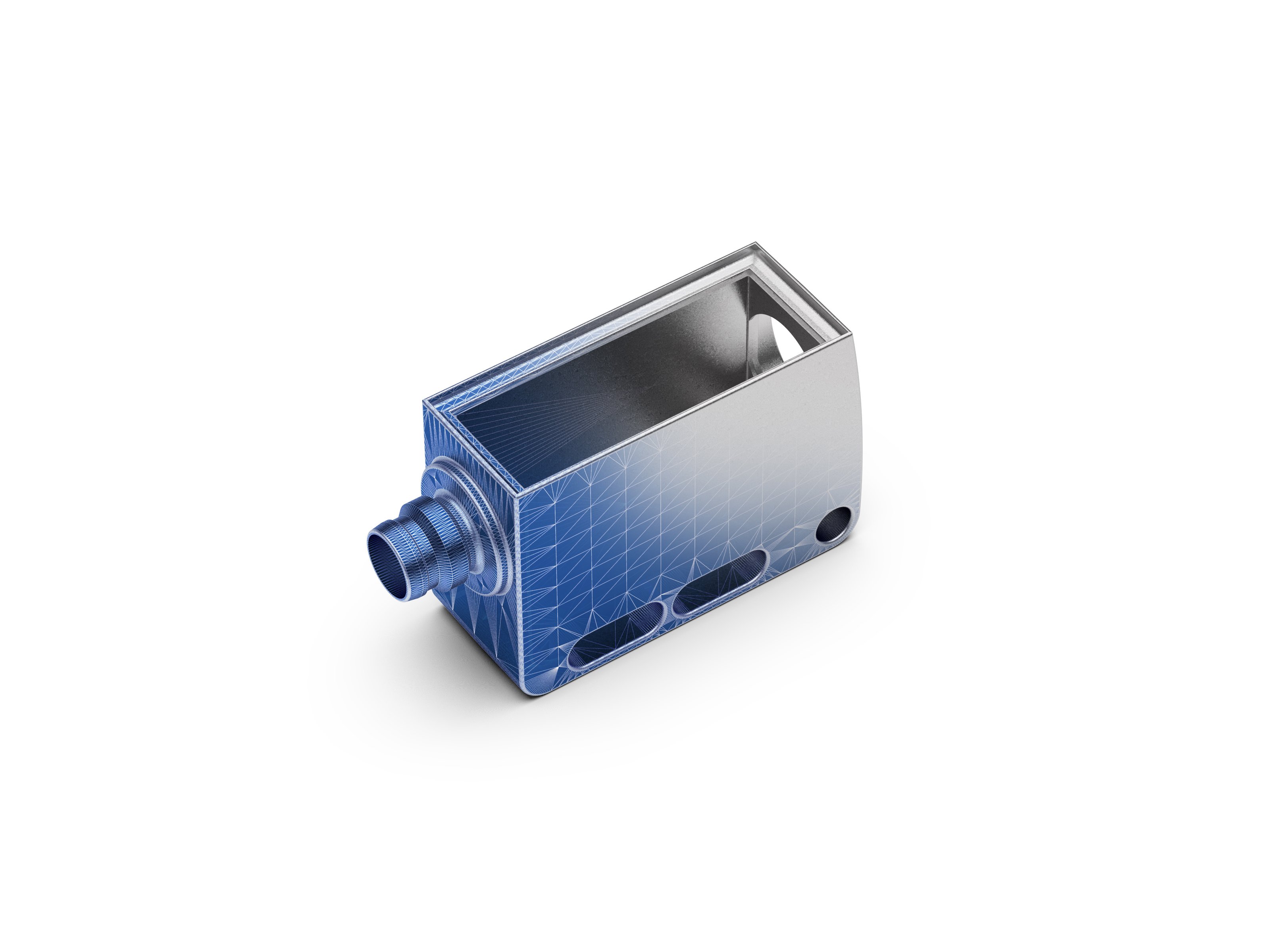

MIM technology, also known as metal injection molding, combines two technologies: injection molding (known from plastic injection molding) and sintering technology.

Due to the implementation of high geometrically complex requirements already in the production process, this technology is referred to as a near-contour manufacturing process.

In this molding process, fine metal powder and thermoplastic polymer resin are mixed in order to obtain a sprayable granulate, the feedstock. The green body obtained in this way is released after cooling in order to detach the plastic. The resulting component, also known as brown body, has a porous surface and is therefore sintered just below the melting temperature.

The advantage of the MIM process is the diverse selection of shaping options and materials. MIM technology is particularly suitable for the production of small and medium-sized metal parts of complex geometry in medium and large series.

While in other processes several components have to be produced separately and assembled to form a component group, one component can be made in one piece in the MIM process. Also bores, threads, undercuts, engravings, and much more can be produced in one production step.

2. An overview of the MIM procedure

1. Mix

In the first step of MIM technology, the fine metal powder is kneaded and heated according to its desired alloy with thermoplastic material as a binder to form a homogeneous powder mixture.

2. Feedstock

After granulation, the metal mixture – the feedstock – is viscous and can now be processed in the injection molding process.

3. Injection molding

At elevated temperature, the feedstock is now injected into a closed mold at high pressure. The form is first filled in completely and then plasticized.

The resulting green body has all the geometric properties of the finished component.

4. Debinding

The cooled green body is now removed from the injection molding machine. The binder is removed in a two-stage process, thermal or catalytic debinding. This can take up to 24 hours.

What remains is a purely metallic, but still open-pore component, the so-called brown body.

5. Sintering

n order to make a precision molded part with the desired geometric and mechanical properties out of the brown body, it has to be sintered at high temperatures.

The molded part can then be treated further if necessary.

6. Final inspection

All our parts are subjected to a comprehensive visual inspection after the MIM process has been completed.

The entire scope of all criteria and measures of quality control is coordinated in a functional manner depending on customer requirements.

3. Video: Process flow in the MIM procedure

4. Origin of metal injection molding

MIM technology has been known for almost a century: The first ceramic housings for spark plugs were already produced in 1920 using metal powder injection molding.

The MIM process did not really arrive in industry until 1980. Initially, MIM was used to produce small, high-precision metallic molded parts for industrial goods.

In the meantime, MIM technology has become indispensable in industry. The MIM process has established itself as a highly economical manufacturing process for large series products, which is used particularly in case of high complexity.

Service – to suit your needs

MIM

The MIM process makes it possible to produce the smallest and most complex moulded parts. Discover the advantages of the process at Richter Formteile. Send you inquiry now!